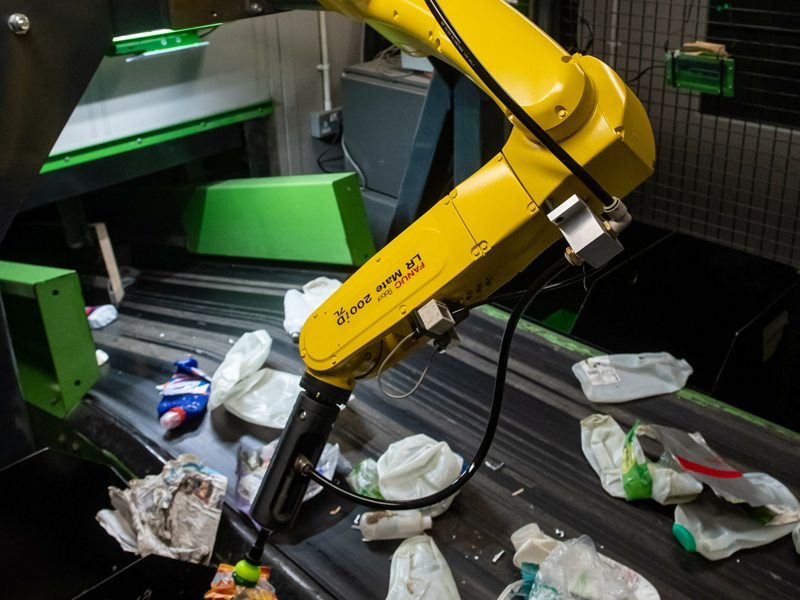

It is of great importance to ensure error-free waste management in order to make natural resources suitable for reuse in a correct and efficient manner during the recycling process. LR Mate 200 iD/4SC, the 6-axis robot developed by FANUC, which produces robotic solutions for different industries, in partnership with smart waste management start-up Recycleye, offers artificial intelligence vision technology to the waste management industry. LR Mate 200 iD/4SC, which can collect 33 thousand products from the recycling line with an accuracy of up to 99 percent in a ten-hour shift, reveals an increase of up to 12 percent in the sorting process and an improvement of up to 10 percent in line output.

While pollution caused by waste is one of today’s most serious environmental problems, the necessity of recycling increases day by day. At points where human power is insufficient to recycle millions of tons of waste every year, the existence of robots that can do this job autonomously makes the process faster and error-free. LR Mate 200 iD/4SC, the 6-axis robot developed by FANUC, the leading leader of numerical control systems in the world markets, in cooperation with the smart waste management start-up Recycleye, brings a new breath to waste management. The robotic waste collection system, which combines FANUC’s more than 60 years of experience in automation with the artificial intelligence support of Recycleye Robotics, automatically separates recyclable materials into different material classes such as plastic, aluminum, paper and cardboard almost perfectly.

A new era in recycling with artificial intelligence vision technology

Stating that the traditional sorting method in recycling is far from meeting expectations in terms of quality and quantity in today’s world, FANUC Turkey General Manager Teoman Alper Yiğit said, “Recycleye Robotics uses artificial intelligence-supported computer vision to identify each item in complex waste streams. The FANUC robot LR Mate 200 iD/4SC, which is at the center of the system, then automatically separates these recyclable materials into different material classes such as plastic, aluminum, paper and cardboard. This system, which is the most accurate and efficient artificial intelligence robotic picking solution available worldwide today, has the ability to collect up to 33 thousand items per robot in a 10-hour shift, working 24/7. The artificial intelligence vision technology integrated by Recycleye Robotics of LR Mate 200 iD/4SC, which is easy to integrate into narrow spaces as a compact, short-armed mini robot, speeds up the work process. “In addition, the robot’s advanced sensors eliminate wasteful movement and can work 24/7 for eight years and still return to the same millimeter point it was told to move,” he said.

It is expected that there will be 89 thousand vacant positions in the recycling sector by 2028

Stating that one important benefit of the artificial intelligence technology developed by Recycleye for recycling facilities is that it provides a solution to the workforce crisis, Yiğit continued: “A report recently published by CIWM revealed that 60 percent of the survey participants had difficulty finding employees last year.” He predicted that there will be 89 thousand vacant positions in the waste and recycling sector by 2028. The LR Mate 200 iD/4SC robot makes a difference with its superior vision system that collects as accurately as an employee and is as sensitive as the human eye. Most importantly, robots do not take breaks, do not slow down, do not get tired or quit their job, eliminating interruptions in the process. This is very important because it can be very difficult to find employees for waste collection. “In addition, one of the biggest advantages of the robot is that it can easily handle hazardous substances that may injure employees in recycling facilities.”