Japan-based CNC, robot and machine manufacturer FANUC, which develops today’s and future robot technologies regardless of sector, maintains its after-sales service quality thanks to the Repair Center it established in Turkey with an investment budget of 250 thousand Euros. The center is FANUC’s second repair point in Europe and provides savings to companies thanks to servo motor, spindle motor, drive and teach pendant repairs. FANUC, which is working to expand the capacity of the center, which promises 100 percent original spare parts and high precision guarantee as well as a one-year repair (renewal) warranty, will expand the existing Repair Center by 5 times within the scope of the new factory investment to be opened in Sancaktepe in 2024.

The Repair Center, which was put into service in 2020 by FANUC, one of the world’s leading factory automation manufacturers, in line with its long-term strategy in Turkey, carries out the fault detection, repair and delivery of products in the fastest way by expert teams with the assurance of after-sales service. The center, which serves in an area of 500 square meters and has the same concept as FANUC’s Repair Center in Europe, repairs products such as servo motor, driver, card and teach pendant in FANUC robots, in addition to servo motor, driver and card products in CNC machines.

No more loss of time and cost

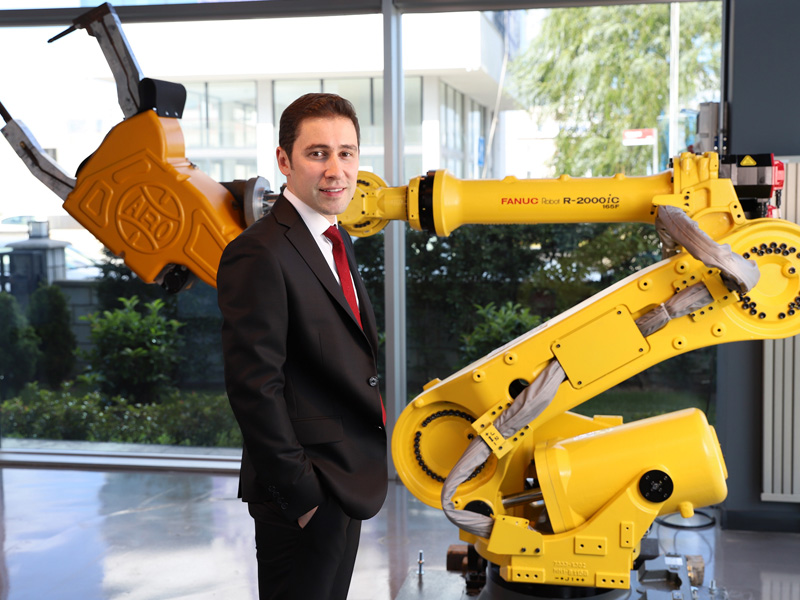

FANUC Turkey General Manager Teoman Alper Yiğit stated that leading sectors such as automotive, automotive sub-industry, medical and mass manufacturing operate with high business volume as a result of the investments made in the industry, and said, “The current situation of factory automation and robot investments in Turkey is quite pleasing. After-sales service also plays a big role in ensuring that companies’ investments in this field are not interrupted. As FANUC, we support the industry and produce comprehensive solutions with after-sales services such as service, maintenance, training and retrofit that we offer to companies in our country. In line with this understanding, the FANUC Turkey Repair Center we offer offers FANUC quality professional, fast and economical repair services instead of unprofessional solutions that cause time and cost losses. “In addition, our customers increase their productivity and profits while minimizing their losses in production.”

Repaired products are delivered with a warranty of one more year.

Stating that they guarantee minimum downtime thanks to the rapid detection, offer, repair and delivery process, Yiğit said the following about the advantages offered by FANUC Turkey Repair Center: “In our center, we guarantee unrivaled quality as well as competitive prices. As a matter of fact, we repair the product with the updates and improvements specified by the original manufacturer. At this point, the use of 100 percent original spare parts is an essential part of our repair process. Our technical team uses specialized testing equipment and not only repairs, but also performs automatic cleaning and painting. We deliver the products we repair, refurbished, brand new in their box, with a one-year product warranty. Our aim is to make FANUC quality sustainable at the time of sale and during the period of use, as well as in the after-sales process.”

The capacity of the Repair Center will increase 5 times in 2024

Explaining that FANUC Turkey Repair Center will be developed to provide a higher level of service, Yiğit said, “With the new factory and technology center that we will commission in Sancaktepe in 2024, our capacity will increase significantly. Our Repair Center will have a volume and capacity 5 times larger in our new building, which will start operating in order to produce the most suitable solution for our customers’ needs and to enable them to get ahead in global competition. “In this way, we will provide service to many more customers at the same time,” he said.