Turkey’s largest valve manufacturer Supsan, besides expanding its product portfolio with new projects, reuses 6 tons of steel body annually by contributing to the circular economy and sustainability. In the machine revision process, the company gives a new life to the machines that have completed their economic life instead of buying the machines they need on the production line from abroad.

Supsan, one of the Borusan Group companies, made a difference with its exemplary project in which it brought a new life to the machines that contribute to the circular economy, within the scope of its sustainability studies on climate, people and innovation. The company, which started to use the machines in the machine park that have completed their economic life, renewed them and used them in the production line, saving 6 tons of steel, 1.5 megawatt-hours of energy and preventing the emission of 1.3 tons of greenhouse gases. The company, which also contributed to the entrepreneurship ecosystem by working with start-ups in the process, supported the development of domestic component and domestic technology manufacturers.

Reducing foreign dependency in machinery investment

Stating that as Supsan, they try to make all their activities sustainable and that they review all business processes in the axis of sustainability strategy, Supsan General Manager

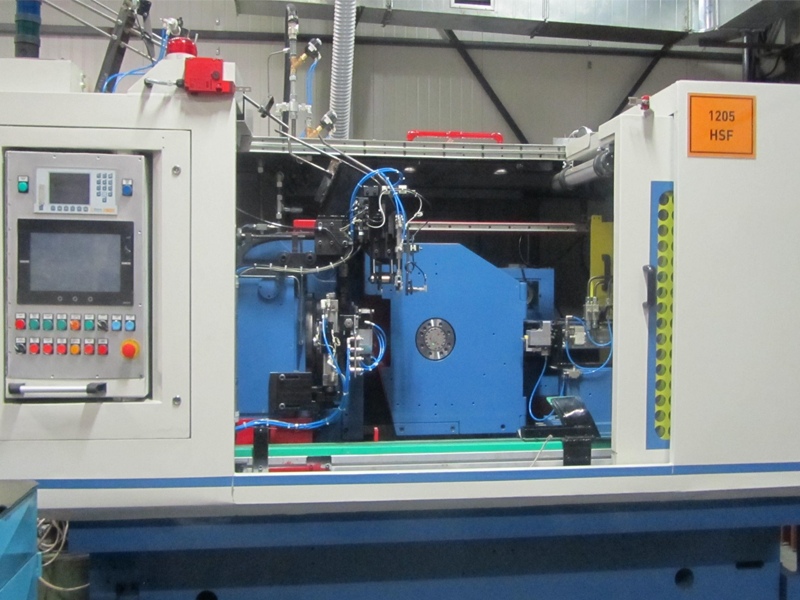

Atınç Ocak said, “Our goal with our project to recycle old machines and give them a second economic life, is to contribute to the circular economy and to eliminate foreign-dependent new machinery investments. it happened. In this direction, we divided old machine bodies into sub-parts and adapted new generation hydraulic, mechanical and electronic systems, giving them a new life cycle. We reuse 6 tons of steel body with 3 machine revisions per year”.

Supports domestic production

Underlining that the machines to be used in production lines are not domestic production, Ocak stated that they aim to support the Turkish entrepreneurship ecosystem and domestic production in this regard, and said, “In industrial production, we think that domestic production will help reduce the current account deficit in the economy, instead of machinery imports. At this point, we have created a team of experts on systems such as electricity, electronics and mechanics with this project, which we have developed apart from valve production, which is our main business. We received support from Turkish entrepreneurs. As a result of technical revisions, we have made the machines, which have reached the end of their economic life, suitable for today’s technological conditions in terms of OHS, environmental impact and technique. We met our own machinery needs without being dependent on foreign sources. Our project, which we save in every sense, contributes to the maturation of the sustainability culture in our company and raises our technologies to the levels required by the day.

Inspired by nature, inspiring the future

Borusan Holding and Group companies see sustainability as the cornerstone of their business processes and handle it in an inclusive way, while conducting their studies in the focus areas of climate, people and innovation. Borusan, which sees sustainability as a stakeholder-based structuring and works to create “benefit” for all life by incorporating nature into its business processes, draws inspiration from the world and inspires the future.